circular economy

- Home

- Circular Economy

circular economy

Join the circular economy

Rethink

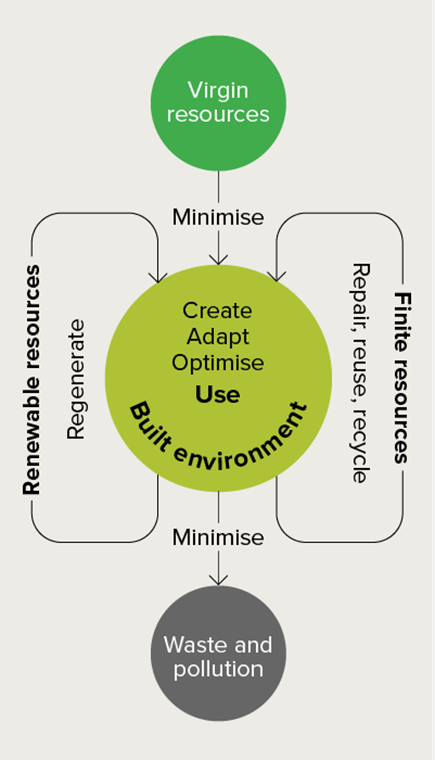

The current emphasis within the built environment value chain is predominantly on construction. However, the concept of the circular economy seeks to re-evaluate and preserve the value of resources, aiming to minimize negative environmental, social, and economic impacts while maximizing positive ones.

Embodied resources

The importance of embodied resources is underscored, recognizing the irreplaceable nature of many natural resources. Attention is required from the moment of extraction, through transportation and processing into construction materials, incorporation into buildings and infrastructure, usage, maintenance, and repair, to eventual removal, and the treatment of resulting 'wastes.'

By-products

Utilizing the nutrient and energy-rich by-products of wastewater and organic solid waste is crucial for achieving circularity in our society. These abundant resources have been consistently available throughout human history, presenting an opportunity to recognize, harness, and maximize their value. This involves treating these streams as valuable resources for energy generation, as well as for use in industrial and agricultural production.

The circular economy is essential

Embracing a circular economy is imperative for addressing future socioeconomic needs, restoring biodiversity, and fortifying stressed natural systems. By adopting circular practices, we can simultaneously reduce carbon emissions and enhance overall societal well-being.

Our Proccess

Adapt and thrive

01.

The emergence of a sharing economy, where ownership costs and benefits are distributed among a larger population.

02.

The concept of "Materials as a Service," wherein suppliers lease materials to users for the lifespan of assets and reclaim them at the end of their life cycle.

03.

The acquisition of materials currently in use to ensure their proper handling at the end of life.

04.

The capture of resources generated as by-products of the built environment's utilization.

Our Proccess

Operate and maintain for circularity

Be Digital and Data-Led

Utilize real-time data to optimize the operation of mechanical equipment, adapting to changing conditions and loads, thereby minimizing component wear.

Demand the Right to Repair

Prioritize repair and refurbishment over demolition and replacement as the default solution, fostering sustainability and resource conservation.

Strengthen Asset Management

Embed circular economy objectives, metrics, and processes into asset management strategies, planning, and delivery. Regular maintenance should be performed to extend the life of existing assets.

Reuse

Extract new value from existing assets and components by rethinking their use, reconfiguring, reconditioning, or remanufacturing.

Adapt, Retrofit, and Refurbish

Extend the life of existing assets to derive value and reduce capital expenditure.

Integrate

Overcome siloed disciplines by integrating capital delivery, asset operation, and maintenance. Ensure seamless connection between people, work processes, culture, objectives, performance metrics, and incentives to enhance overall efficiency.

Commission

Make performance targets an integral part of procurement, ensuring that new assets or interventions meet expectations and are sustained over time. Provide operational staff with the necessary understanding and capabilities for maintaining performance post-handover.

Take Every Opportunity

View all interventions involving adaptation of existing assets as opportunities to recover resources from the built environment, contributing to the replenishment of available resources.

Our Proccess

Plan for circularity

Set the objective

Build circular economy principles and objectives into your organisational strategy, planning and delivery.

Challenge need

Resource consumption can be substantially reduced by challenging and changing user behaviours. Cutting back user demand can sometimes remove the need for construction of new buildings or infrastructure altogether.

Use nature-based solutions

Hard engineering can sometimes be minimised or avoided by using nature-based solutions. Using nature-based solutions where possible will also bring wider environmental and social benefits.

Pursue efficiency

Further reduce the need for new construction by squeezing the maximum performance from existing assets and adapting redundant assets to new uses.

Manage stocks and flows

View the built environment as a bank of materials that can be drawn on for resources as an alternative to first-use materials. Deliver all materials, components, assemblages and assets with digital certificates that record and track their provenance, composition, use and condition.

Conduct lifecycle assessments

Assess the service life of assets, components and materials, and their availability, utility and value, in order to understand when resources can be released for reuse and potential trade-offs between their value in current and future uses.

Develop the circular ecosystem

Enable the flow of resources by, for example, locating assets that produce too much heat close to assets that require heating, such as an underground station and a hospital, or an advanced anaerobic digestion facility and a commercial greenhouse. And build local ‘ecosystems’ of companies to manage stocks and flows through the ‘bank of materials’.

Our Proccess

Design for circularity

Incorporate BIM and digital twins

Utilize digital asset models to address requirements at every stage of the asset lifecycle, from construction to decommissioning. Establish a platform for effective asset management.

Foster design for reuse

Strive to maintain existing assets in their current state, without modification. If relocation is necessary, design assets for reuse in new locations with minimal alterations.

Emphasize design for longevity

Acknowledge that ensuring durability, climate resilience, or additional capacity may require an initial investment in more resources. Prioritize designs that facilitate through-life adaptation and refurbishment.

Prioritize design for construction

Address the issue of substantial material wastage on construction sites by creating designs that are easy to build and adhere to standard dimensions and units. Minimize waste caused by over-ordering, transportation and storage of unused materials, weather-related damage, poor supply chain coordination, and human error by adopting modern construction methods.

Advocate for design for adaptation and deconstruction

Plan for the removal and replacement of components, disassembly, and clean separation of materials to prevent the loss of value.

Stress design for efficiency

Optimize resource use to save costs and reduce carbon footprint. Design with a focus on sustaining the value of materials throughout their lifecycle or across multiple lifecycles.

Encourage design for standardization

Simplify the integration and disassembly of assets by utilizing products and modules based on industry standards and common platforms.

Our Policies

Procure, manufacture and construct for circularity

Our Values

Sustain and recover value

Our Proccess

A bank of materials

01.

Logging, quantifying, and categorizing materials, meticulously tracking their lifecycle within the built environment, creating material passports, and maintaining inventories for each asset.

02.

Monitoring the performance and condition of assets, facilitating proactive maintenance and repair for optimized efficiency and longevity.

03.

Identifying the appropriate timing for asset replacements.

04.

Tracing resources from their 'in-use' phase to being 'in-stock,' including processes like reconditioning, remanufacturing, or recycling.

05.

Aligning supply with demand to maximize resource efficiency.

06.

Measuring and reporting inputs of new 'virgin' resources, like energy and water required for asset operation, thus constructing a comprehensive understanding of resource intensity over time.

Our Proccess

People all the way